PROJECT

High collection efficiency of positive, singly charged particles in the range from 2 to 100nanometers Flow and voltage adjustments Built-in pump and flowmeter

Now you can sample charged particles, typically from the output of a Differential Mobility Analyzer (DMA), onto sample substrates for analysis. The Model 3089 Nanometer Aerosol Sampler (NAS) allows you to control the spot size of the deposition using two electrode sizes to get a uniform deposition size that is optimal for your analysis system. For your convenience, the instrument contains a high-voltage negative power supply, pump, and LCD display. The NAS is optimized for use with a Model 3080N Electrostatic Classifier, which contains a Model 3085 Nano DMA.

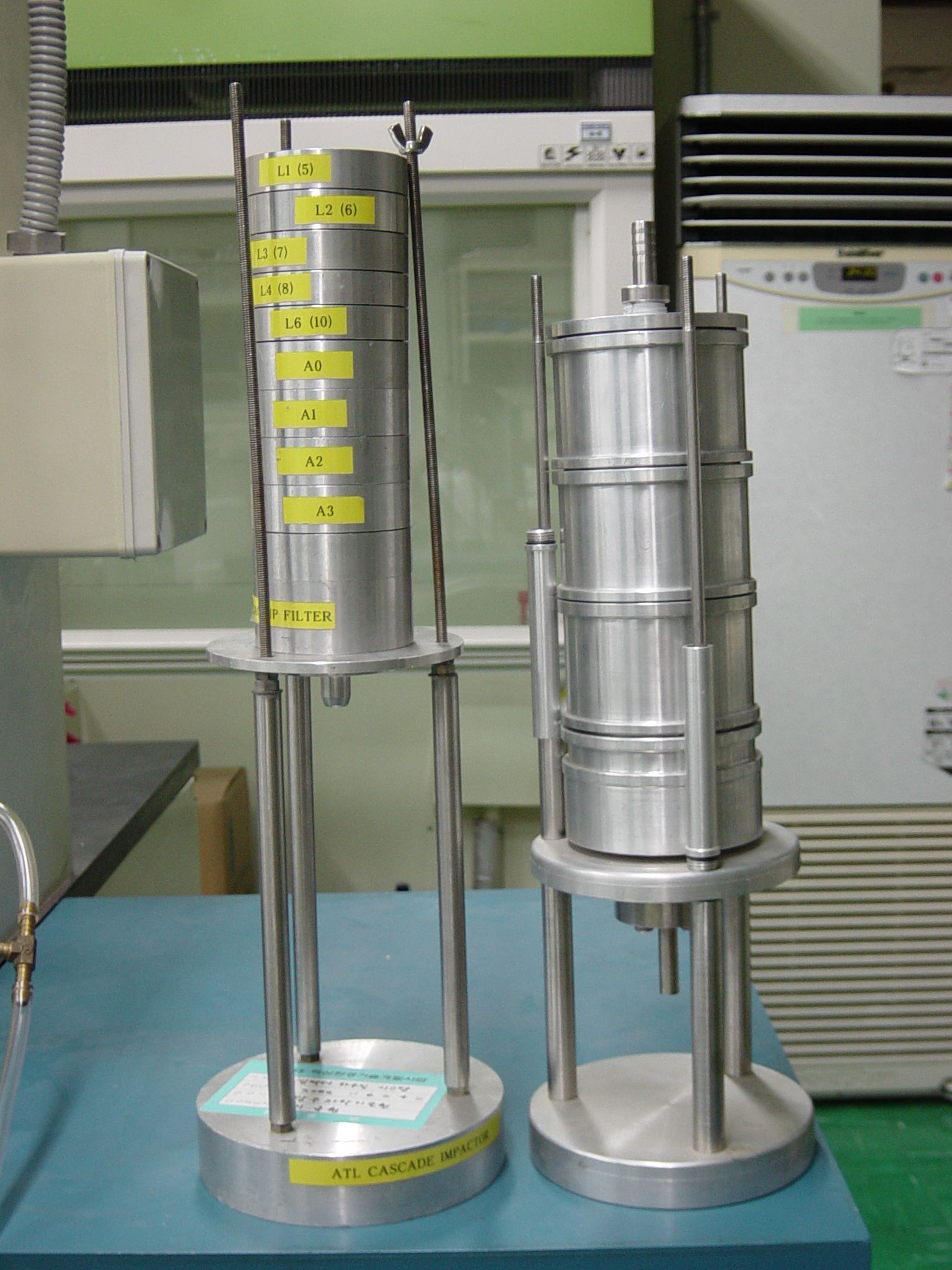

The Six Stage Viable Impactor is comprised of an aluminum inlet cone, six jet stages, glass petri dishes, and a base plate held together by three spring clamps and sealed with O-Ring gaskets. Each sampling stage has 400 precision machined jet orifices. The Six Stage Viable Impactor requires a flow rate of exactly 28.3 lpm (1 CFM).

The collection and assessment of aerosol samples is very simple. Petri dishes containing an agar medium appropriate for the micro-organisms that may be encountered are placed in the instrument and a sample of air is drawn. The petri dishes are then removed, incubated, and counted by an accepted method.